See video for info on the Irritrol Remote Control system and how to wire it to any sprinkler timer.

See video for info on the Irritrol Remote Control system and how to wire it to any sprinkler timer.

If the dial breaks off or gets very difficult to turn, you have some options.

I often get questions about what it means when the timer says Opn or Open. This message comes from the term ‘open circuit’ which means that the timer tried to turn on a valve, but the circuit was open, meaning a wire is disconnected, broken, or the solenoid is broken.

Typically this problem is caused by loose wiring or a bad solenoid. Examine the connections at the timer and at the valves, typically found in a ground box.

It could also be caused by a timer or a back terminal board problem. If your wiring looks good, you can send the timer and back terminal board to us for repair.

If you only have one valve indicating an Open condition, you can try swapping wires with another valve to confirm that it’s a valve or wiring condition. E.g., if station/valve #1 works and #2 is currently saying Open, then swap wires for #1 and #2. Then try to turn on the 1st and 2nd stations using the timer’s manual function. If the first station works and the 2nd station displays the Open message, then the problem is likely with the timer or backboard, send it in for repair. If however, you now see station 1 reporting an open message, then the wire connections or solenoid is bad. Solenoids usually fail shorted instead of open, but either is possible. You can check either with a

Check wiring and/or replace the solenoid using the information below.

For additional testing, you can follow some of the steps to test the transformer. Start with Check #3 on this page. If you’re able to operate the valve, you know the transformer, wiring, and valve are good.

We hope this helps, if so, consider making a small donation on our donation page; we really appreciate it.

Transformers rarely fail, and when they do, it’s usually caused by people not turning the power off when they are moving wires and the 24VAC wires touch. Sometimes a failed solenoid could cause transformer problems but the timer usually shuts off and issues a FUS message before the transformer is damaged. Some models also have fuses on the back terminal board that helps protect it.

A note of caution – the transformer is connected to your household 110/120VAC power, which is dangerous. Be sure to take precautions by turning off the power before working on the unit. You should not attempt it unless you are experienced enough to do so. This post does not contain sufficient information to work with these voltages safely; If in doubt, contact someone who is qualified.

Most of the time people think that the transformer is bad when it isn’t, Follow the DIY page topic on ‘How to test if the transformer is good’ to know for sure.

As one optional and additional check before you tear it apart, you can use a multimeter to perform some simple transformer checks.

Turn off the power and disconnect the AC power connection at the bottom of the transformer case on the right-hand side. There should be black, white, and green wires. Remove the timer ribbon cable from the back terminal board. Your multimeter’s resistance measurement settings should be set to the lowest resistance range. e.g., 0-50ohms…

If either one measures open, you know the transformer is bad and must be replaced.

If you conclude that the transformer is bad, you can use the following information to help you understand how to replace it. I generally start on the left side and work my way around counter-clockwise. REMOVE THE KEY FIRST, or it can be difficult to remove later.

After removing the case, you’ll see how the transformer is connected into the case. You can often find them on ebay or at a local landscape supply store.It should be rated for 1.25A, 24VAC.

The transformer typically looks like this.

If this info has helped you, please consider making a donation – we depend on you to keep this information available.

Note, some newer transformers have an additional green wire coming out the bottom (reference the photo above). Keep reading for more information about it.

Background Material for understanding grounding, green wire ground, surge protection:

Irritrol has had surge protection circuitry on their newer back terminal boards for a long time. It’s provided by those “blue” capacitor looking components that are actually MOV or TVS devices. They do not not work unless they have a ground path for surge current follow. Irritrol’s previous transformers never brought the ground wire out into the compartment where the back terminal board is for you to easily access it. It was assumed that the ‘user/installer’ would run a separate ground wire to the back terminal board for this purpose. Unfortunately, there was no way to route the ground wire from the ac mains to the compartment without drilling some holes and adding your own wire. Alternately, and preferably, the user was expected to bring in a separate ground wire through the portal with the valve wires and tie it to a grounding rod. Adding your own grounding was a hassle and expense and basically no one ever did it. I’d estimate that 99% of customers never had a ground wire hooked up at all, causing the surge protection circuity to be useless.

To fix this, (20+ years later) Irritrol started manufacturing transformers with the AC ground wire passed through from the AC Mains side through to the main compartment. There are now 3 wires; red, yellow, and green (or maybe green/yellow-stripe). Although not as good as having your own grounding rod, this is much better than nothing and now that it is “conveniently accessible”, people will or at least should use it.

Now to answer your question.

If you have a newer transformer with a green wire that wasn’t there before, connect it as follows:

1) If your terminal board has a GND or Earth Ground screw terminal, connect the wire to this terminal.

2) If you don’t have that terminal, but have a smaller, unlabeled screw terminal located below the 24VAC terminals, connect it to this terminal.

3) If you don’t have either of the above terminals on your back terminal board, simply connect the green wire ground in the VC terminal

with any other VC wires. (Usually these wires, by convention, are white, but they don’t have to be)

4) Of course, if you have your own grounding system (rod, etc.) already in place, use it instead and just cap the green wire off with tape or a wire nut so it doesn’t touch anything else.

Note that it does not matter what order you put the red and yellow wires on the 24VAC terminals; either way is fine, but “R”ed on the “R”ight is a common convention.

If this has been helpful, please consider making a donation on my site; I don’t get paid by Irritrol or any company for the service and the proceeds go towards kids education and to keep this site going.

Good luck,

Brian, Jen, Meghan and Ben – the rainDialDoctors

Note: If you see — when you try to set the day of the week to on or off, it means you’re in skip days mode. Usually, the LCD also displays “skip days”. To turn off skip days, set the dial to skip-days and press the “-” button until it says off. Then you’ll no longer see “—” for the days of the week.

To fully understand the skip-days setting, read the following:

Question: When I set the skip day number to 1 – does that mean it skips every other day?

Bill

—————

Hi Bill,

Surprisingly no, it doesn’t. The Irritrol RainDial RD600 Skip days feature is often misunderstood and difficult to understand, so thanks for the question. The short answer to your question is no. setting it to ‘1’ will water every day. This should help explain why:

The skip days function controls when a schedule will run. If you were not doing skip days, you would specify the days of the week you want the schedule to run by setting for example Tuesday to “ON” and the other days “OFF”. The timer would then run the schedule every Tuesday. In skip days mode you are scheduling the timer to run the schedule every # days where # is the skip days value.

I like to think of the skip days feature as having a daily incrementing counter that starts at 1 and goes to the number you specify and then repeats. E.g., for a skip days setting of 3, the timer’s counter would count like this: 1,2,3,1,2,3,1,2,3. Whenever the counter matches the skip days number, the watering schedule will run. In this example the schedule would run every 3rd day. The term skip days is sort of confusing.

Instead of ‘skip days’, think of it as ‘water every # days.’

So if it’s 2, it waters every 2nd day, which is every other day: 1,2,1,2. If you set it to ‘1’, it waters every 1 day, which is ‘every day.’

Although I’ve answered your question, one may ask: How do I know what today is in the sequence of days? You determine that by putting the dial on ‘Today.’ It will show you the current number in the sequence. You can also change the number of ‘today’ by pressing the +- buttons when in programming mode.

E.g., if you have skip days set for 3 and you want it to water tomorrow, set ‘today’ to ‘2’.

I hope this helped, if it does, consider sending us a high $5, we’d really appreciate it.

Thanks,

Brian – aka the Irritrol RD600 Rain Dial Doctor for Irritrol timers

When Irritrol RainDial batteries keep draining faster than they should (usually they last at least a year or more), it is a sign that the controller is failing, but has not failed completely.

As the parts fail they can degrade slowly and the battery ends up providing power to compensate. However, this causes the battery to drain faster, meaning it may last a week, or month instead of a year. Eventually you’ll have to replace it more and more frequently until even a new battery won’t be enough for it to work.

There’s no way to really predict when a new battery will not be enough to make it work. One thing is for sure: “you’re living on borrowed time.”

You can wait if you want, but it’s usually better to get it taken care now, otherwise Murphy’s law usually kicks in and it’ll fail right before you are headed out on a long vacation 🙂 They often are intermittent as they’re failing, so it will not water, but when you notice the dying plants, but when you test it, it’ll seem to be working. When it’s “on the edge of complete failure” it sometimes works, and other times not. The temperature often effects the behavior.

Irritrol RainDial timers are well made an with a quick repair can last another 10 years. Repairs are the core of our business and we’d appreciate it if you’d select us to do the it.

This is one of the features in the new -R series of Irritrol sprinkler timers. It’s described in the manual in more detail but basically does this. The Sprinkler timer has a pump control signal that normally turns on when a particular valve is turned on. Most people I know don’t have a pump to boost pressure in their irrigation system so it’s not a common feature for the general urban irrigation system. If for some reason you did not want the pump to come on when a particular valve was on, you can turn it off.

You can change the P:ON/OFF setting by doing the following:

If you don’t have a pump, it doesn’t matter whether you turn this feature on or off. If you do have a pump, you’ll know what to do.

If you’re not expecting this to appear on the LCD, you probably need to slide the switch to the “run” position instead of “set programs.”

How does this happen? Some people try to manually turn on a valve but accidentally have the switch in the set-programs position instead of ‘run’ when they add minutes.

I hope that helps,

The RainDialDoctor

For help programming the RainDial RD600-1200 series sprinkler/irrigation controllers, see the following programming guide and then review the manuals above. This is a quick guide, not the user manual. If you’d like to see the full manual, click here.

Irritrol Programming Templates and Tips

Usually when this happens, it’s caused by the door having a fair bit of friction due to dust or dirt.

To avoid spam and other problems, your comment won’t appear until it’s been approved. Don’t worry if you don’t see it right away.

To add a question, go to the bottom of the page, fill in the comment and click Post Comment.

Please look at the DIY Troubleshooting section before posting; answers to most questions can be found there.

You can also reply to other people’s questions if you like. (Thanks for helping)

Please try to include the following with your question, list:

1) the date code (located under the battery),

2) the model number shown on the face of the controller (usually below and to the left of the dial, e.g., RD-600 or RD-600-R).

3) Color (mostly Gray or Blue) based on the example rainDials shown at the top of the page.

Three notes about this topic are worth mentioning

This page will guide you through determining what the problem is likely to be.

First do some simple checks: You may want to read the rest of this page to be sure, but in general:

We’d appreciate your business if the following troubleshooting information suggests it needs repairing. Thanks!

The rest of this page provides more detailed troubleshooting on how to check for a bad solenoid.

Bad solenoids are usually indicated by the FUS message, but on rare occasions, it will blink off. Try turning on a valve manually (by selecting a valve, adding minutes with the + button) and the LCD just goes back to OFF, it’s typically one of the following:

A good way to tell the difference is if the problem occurs with more than one valve. If more than one valve shows the problem then it’s a problem with the controller. If only one sprinkler valve exhibits the problem, you can try these things:

If you determine the solenoid is bad, they are fairly easy to replace. I usually take a photo of the valve to a local landscape store so they know what I’m looking for.

We hope this was helpful – if it was, use our services or consider a friendly donation. Thank you.

Click here to contact us or here to see How do I send it in for repair?

If the valves turn off, it’s likely a timer or usually a programming issue. See the remaining items below.

(This and all information on the RainDialDoctor website is copy-righted by Brian Keller.)

Note that this information applies to the Irritrol RD-600, RD-900, and RD-1200, but the concepts presented can be applied to troubleshooting nearly any irrigation timer.

If you URGENTLY NEED TO STOP THE WATER, turn off the timer. If that doesn’t work, then close the valves as shown on this page.

Before you read further, it’s important to know if the timer has turned on a valve vs. when the valve is on even when the timer doesn’t “think” it should be on. Here’s how to tell the difference:

Read this link. to determine if the timer is trying to turn on a valve or not, then choose the appropriate topic below

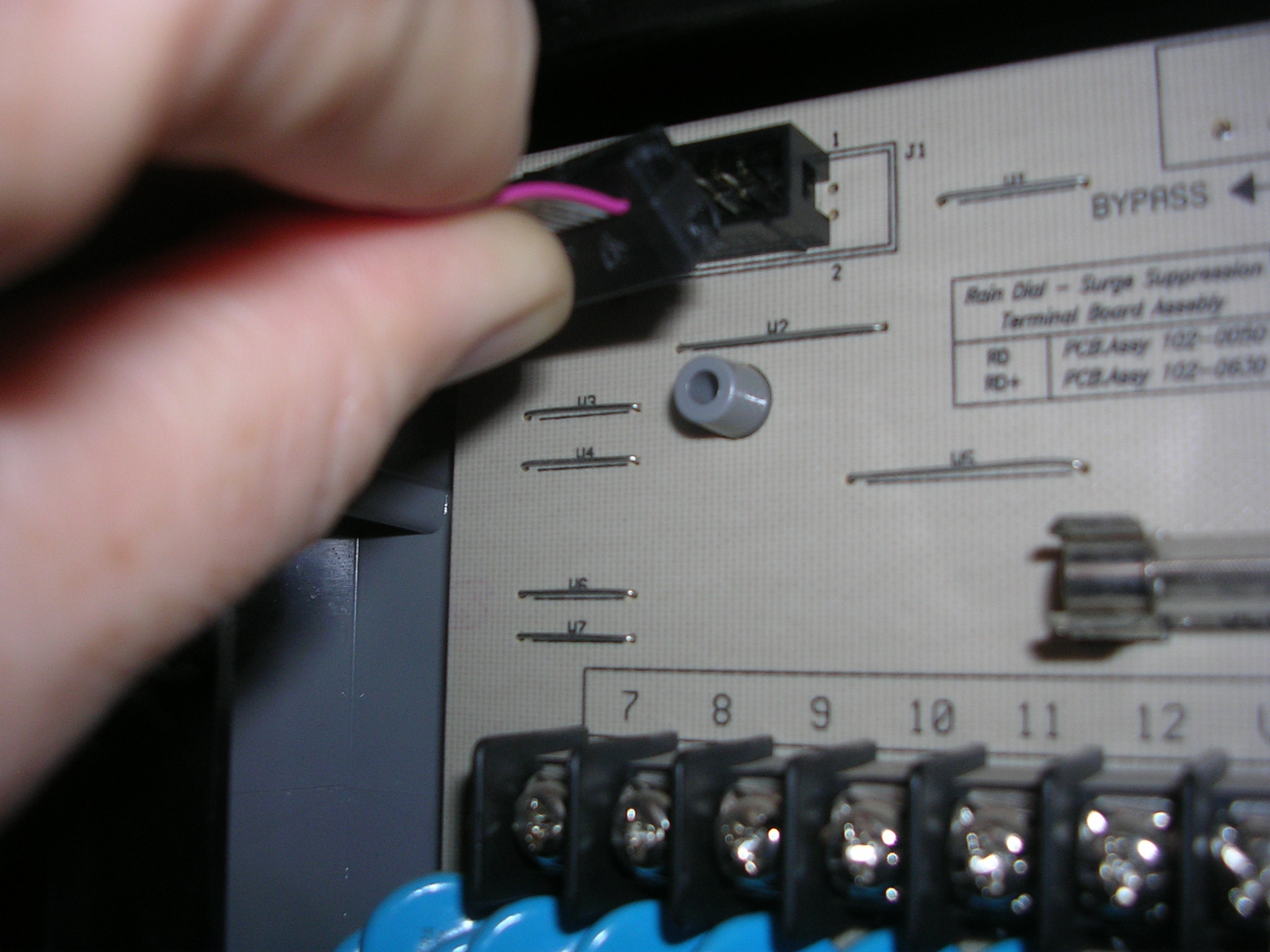

Irritrol RainDial troubleshooting – removing the ribbon cable

If the valve turns off, it’s likely a problem caused by the controller; plug the ribbon cable back in and: